Fabrication and Characterization of Polymer Rechargeable Lithium Ion Battery

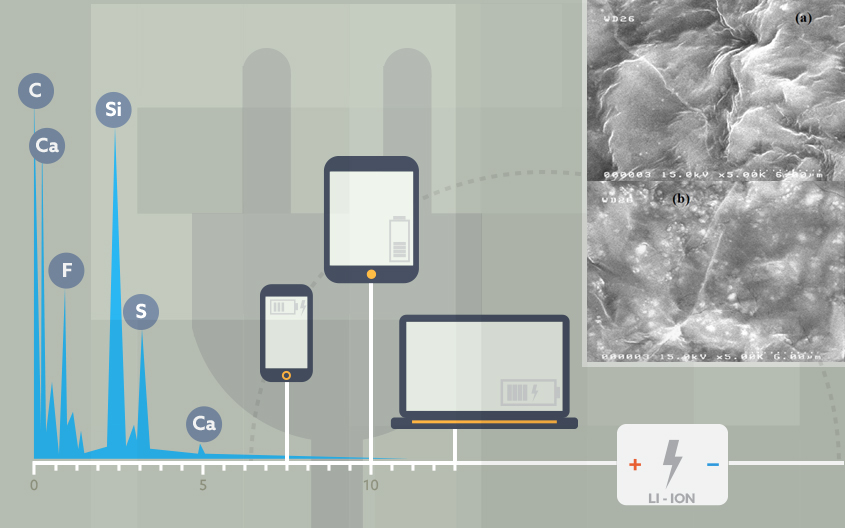

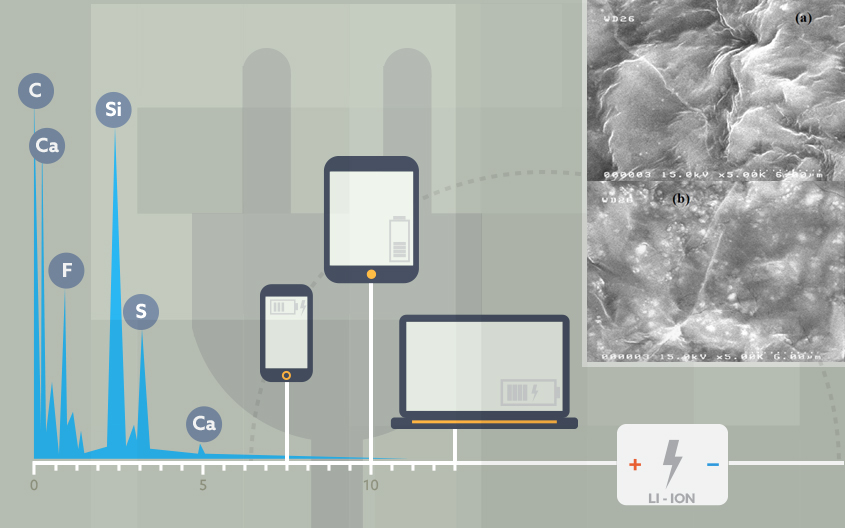

The PEO−EC−LiCF 3 SO 3 −Al 2 O 3 battery with the high ionic conductivity of 2.970 × 10 -5 S/cm produces the stable output voltage compare to other battery. The simulated current density using Monte Carlo method is 44.6 mA/cm 2 in our model. This is PEO polymer battery is rechargeable, weigh less, non-toxic and environmental friendly. The PEO polymer electrolytes can be used to fabricate the polymer lithium ion battery which is marketable for smart-phone, netbook, digital camera and iPad usages. In this study, the polymer electrolyte materials are prepared using the solution cast method. Polymers, plasticizers and lithium salts are added accordingly with appropriate solvent. The polymer electrolyte samples for lithium battery can be conceived as a system composed of four components: a polymer, for example, polyethylene oxide (PEO); a lithium salt, like LiClO 4 , LiPF 6 , LiBF 4 or others; a filler, TiO 2 , SiO 2 , Al 2 O 3 or others; and a plasticizer, such as propylene carbonate (PC), dimethyl carbonate (DMC), ethylene carbonate (EC) etc. The polymer rechargeable lithium ion battery will be fabricated and tested in this work as a final product.

he MMU Digital Futures Research Hub is a multi-disciplinary platform for research on the digitalization of our society. The goal is to foster innovative, cutting-edge multi-disciplinary research, and to provide outstanding training for talented young scholars and students through 8 research institutes.

The hub is a community and industry centric entity, with 20 professor chairs that brings together universities, governmental and industrial research organizations, as well as state and federal governments.